One flow

Author: b | 2025-04-24

Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct Flow Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct Flow

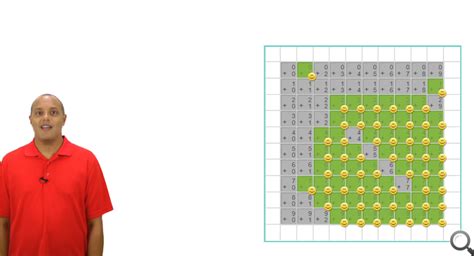

What is One Piece Flow? (Continuous Flow Single Piece Flow)

Themselves. A pure experience of using a calculator as with a desktop application. An exclusive version of the calculator is available to registered users. Choose the right subscription duration and start using the exclusive service. Exclusive Description q - volumetric flow rateFluid flow rate in terms of units of volume per unit of time ṁ - mass flow rateFluid flow rate in terms of units of mass per unit of time V - velocityFlow velocity in terms of units of distance per unit of time D - internal diameterInternal circular pipe diameter Cv - flow coefficientIn imperial units - gpm Kv - flow coefficientIn metric units - m3/h p - pressureFluid pressure at the start of the pipe for gas density calculation based on the ideal gas state equation ρ - fluid densityMass per unit of volume Calculation setup Select value to calculate. You should enter not selected one. q/ṁ Calculate flow rate ΔpCalculate pressure drop Cv/KvCalculate flow coefficient Select value to input. You should enter selected one. The other one will be calculated q volumetric flow rate ṁ mass flow rate Select value to input. You should enter selected one. The other one will be calculated. Cv flow coefficient in imperial units - gpm Kv flow coefficient in metric units - m3/h Select value to input. You should enter selected one. The other one will be calculated. v flow velocity D internal pipe diameter When is this calculator suitable? To select a size of a control valve, you should

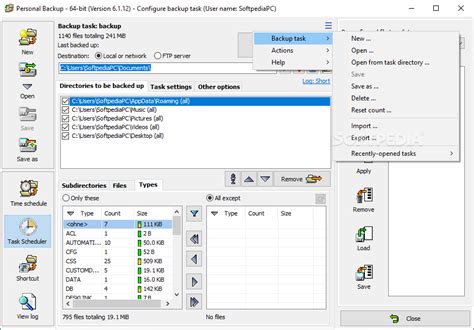

Adjusting the layout of one flow in a project of many flows

The protocol that permits this is called NetFlow. It was created by Cisco Systems several years ago but it is now commonly used in one form or another on networking equipment from most major manufacturers.What Is NetFlow?NetFlow was developed by Cisco Systems and was introduced on their routers to provide the ability to collect IP network traffic as it enters or exits an interface. The collected data is then analyzed by network administrators to help determine the source and destination of traffic, the class of service, and the causes of congestion.The flow exporter aggregates packets into flows and exports flow records towards one or more flow collectors. This is the component that is running on the monitored devices.The flow collector is responsible for reception, storage and pre-processing of flow data received from a flow exporter.Finally, the flow analyzer is an application that is used to analyze received flow data. Analysis can be used for traffic profiling, or for network troubleshooting.How NetFlow WorksRouters, switches and any other device that supports NetFlow can be configured to output flow data in the form of flow records and send them to a NetFlow collector. A flow is a complete conversation in the IP sense. The device preparing flow records normally sends them to the collector when it determines that the flow is finished either through aging–there has not been any traffic within a specific timeout–or when it sees a TCP session termination.The flow record contains a lot of information about the flow. It includesTrigger One Power Automate Flow from Another Flow

Sure the Flow EZ or Push-Pull is already in sleep mode before disconnecting the power. Page 15 The Flow EZ or Push-Pull is ready to be used, Simply turn the dial to start. user's manual in on the next page: LineUp series Allowing one to get the most out of the devices. Page 17 LINEUP SERIES USER’S MANUAL PRODUCT OVERVIEW SETTING UP A faster way to change the pressure Add a FLOW UNIT Flow rate control Inject a volume Flow-related setting Liquid type SYSTEM EXPANSION Create a multi-channel configuration Mixing different pressure range LineUp Adapt COMPUTER CONNECTION LineUp Link... Page 18 PRODUCT OVERVIEW LineUp Flow EZ Pressure controller FLOW UNIT port to the flow sensor Pressure supply transmission used only in multi-channel configuration Pressure outlet to reservoir Pressure inlet from pump or compressed air supply... Page 19 PRODUCT OVERVIEW LineUp Push-Pull Pressure controller FLOW UNIT port to the flow sensor Pressure supply transmission used only in multi-channel configuration Pressure outlet to reservoir Positive pressure inlet from pump or compressed air supply Vacuum inlet from vacuum pump... Page 20 PRODUCT OVERVIEW Change pressure command Set/Apply pressure Navigate Command set in menu in menu Unlock button used only in multi-channel configuration P=0 button press once to set pressure to 0, press again to return to original pressure, hold to put into sleep mode Left button press to rotate the display/go back Right button... Page 21 SETTING UP A faster way to change the pressure Classic way: Turn dial in the "Operation window" to immediately change the requested pressure, this command is continuously Flow EZ or Push-Pull. applied by the ON/OFF way: Click on the dial, set the pressure requested pressing the dial faster... Page 22 SETTING UP Add a FLOW UNIT The FLOW UNIT is Fluigent's flow rate sensor. When a FLOW UNIT is added, one can use the Flow EZ or Push-Pull to: • Monitor the flow rate in the microfluidic set-up Directly control the flow rate locally •... Page 23 SETTING UP Connect the FLOW UNIT to the Flow EZ or Push-Pull dedicated port Use the on the back of the pressure controller to connect the flow sensor. Once a FLOW UNIT is connected, the automatically detects device it and the "Operation window" will flow rate measurement. Page 24: Flow Rate Control Abnormal flow rates may reflect problems in the microfluidic set-up (leakage, clogging, etc.) See Fluigent FAQs on www.fluigent.com. Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct Flow Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct FlowExploring Branching Strategies. Git-Flow, One-Flow and Trunk

Across a wide range of sizes and models. Copper has a melting point of 1,083°C and a normal maximum operating temperature of 225°C. Nickel, with a melting point of 1,453°C, can be used for specialist applications requiring higher temperatures and fluids aggressive to copper, with a maximum operating temperature of 350°C.Following brazing, the units are tested for leaks, using inert gas, ensuring that there is no external or internal leakage. They are pressure-tested typically at a pressure 50% higher than the normal maximum operating pressure.BPHE operationThe operating principle of a BPHE is based on the simple transfer of heat energy from the warmer media to the cooler one. The secondary side always has one more flow channel than the primary side – provided by the first and last channels – and contains the secondary fluid surrounding the primary channel. The secondary circuit also has a lower pressure drop because it contains one more (parallel) channel.The flow arrangement can be either counter flow or parallel flow (Figure 2).Figure 2: Temperature profiles for counter flow and parallel flow BPHECounter flow is preferred, since it enables a closer approach temperature (this is the temperature difference between the inlet of the primary and the outlet of the secondary flows), as well as a greater total heat exchange. As with any heat exchanger, the heat transfer from one flow to the other through a BPHE can be determined from U A ΔTLM, where U is the average thermal transmittance from one flow to the other (W·m-2·K-1); A is the overall heat transfer area (m2); and ΔTLM is the log mean temperature difference between the two flows.ΔTLM – often referred to as LMTD – is determined from the entering and leaving primary and secondary temperatures:So, for example, referring to the recommended system temperatures in Table 2Pipe flow calculators in one place

‘Yes’ side of the flow path to delete the records contained in the selectedRows collection of the data table. And that is it! The flow now looks like this: When we debug the flow with a Contact that is currently subscribed to one Email List, the first screen looks like this:On the next screen, we make some selections: When we push the “Update Selections” button, the flow makes the changes and ends. In cases when used on an actual record page or Salesforce Experience Site page, the flow would automatically start over and show us the first screen again with our changes made: ConclusionThis Flow was a lot of fun to build, and we hope you learned something! This is just one example of the great things that can be done with Salesforce Flows. Follow us on social or subscribe to our monthly newsletter to stay up-to-date on all things Salesforce and automation. Other blogs to explore:• Salesforce Flow Basics: Data, Elements, Decision and Assignment• Using Slack Workflows to Manage Customer Support Requests• Salesforce Flow Basics: Loop, Collection Sort, and Collection Filters• Salesforce Flow Basics: Screen, Pause, Action, and Subflow• Salesforce Flow Basics: Variables, Collections, and Formulas About the Author Jonathan DavisDoble ONE Flow Letal - YouTube

Through our Flow API and RxJava implementations one-by-one.4. Implementation With Flow APIThe Flow APIs in JDK 9 correspond to the Reactive Streams Specification. With the Flow API, if the application initially requests N items, then the publisher pushes at most N items to the subscriber.The Flow API interfaces are all in the java.util.concurrent.Flow interface. They are semantically equivalent to their respective Reactive Streams counterparts.Let’s implement VideoStreamServer as the publisher of VideoFrame.public class VideoStreamServer extends SubmissionPublisher { public VideoStreamServer() { super(Executors.newSingleThreadExecutor(), 5); }}We have extended our VideoStreamServer from SubmissionPublisher instead of directly implementing Flow::Publisher. SubmissionPublisher is JDK implementation of Flow::Publisher for asynchronous communication with subscribers, so it lets our VideoStreamServer to emit at its own pace.Also, it’s helpful for backpressure and buffer handling, because when SubmissionPublisher::subscribe called, it creates an instance of BufferedSubscription, and then adds the new subscription to its chain of subscriptions. BufferedSubscription can buffer issued items up to SubmissionPublisher#maxBufferCapacity.Now let’s define VideoPlayer, which consumes a stream of VideoFrame. Hence it must implement Flow::Subscriber.public class VideoPlayer implements Flow.Subscriber { Flow.Subscription subscription = null; @Override public void onSubscribe(Flow.Subscription subscription) { this.subscription = subscription; subscription.request(1); } @Override public void onNext(VideoFrame item) { log.info("play #{}" , item.getNumber()); subscription.request(1); } @Override public void onError(Throwable throwable) { log.error("There is an error in video streaming:{}" , throwable.getMessage()); } @Override public void onComplete() { log.error("Video has ended"); }}VideoPlayer subscribes to VideoStreamServer, then after a successful subscription VideoPlayer::onSubscribe method is called, and it requests for one frame. VideoPlayer::onNext receive the frame and requests for a new one.Home Page - Flow One Wheels

One of the challenges you may face with large properties is how to fit the required irrigation in the window allowed. If only time-based irrigation scheduling is used, some stations may not be able to run during the window. One solution to this problem is to create schedules based on the system’s flow capacity. IQ4 Central Control offers two standard features, FloManager™ and SimulStations™, which do not require the addition of flow sensors or meters to create schedules based on flow capacity. The installation of flow sensors will only improve the accuracy of the flow data and you may be able to optimize the schedules even more.FloManager adds basic hydraulic management features to your system to ensure that sufficient water pressure and volume is available to operate all stations. Although it is helpful, flow sensing hardware is not required to use FloManager. You can manually enter estimated flow rates even if flow sensing hardware is not installed.Example of Irrigation Schedule Not Using FloManagerIn this example only time-based programming is used. The watering schedules take almost 14 hours to complete, and cannot be completed within the watering window. The peak flow rate during operation is 88 GPM, only 73% of the system’s total flow capacity, which is 120 GPM.. Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct Flow Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct Flow

Get Started - One Flow Yoga

1. Flow Collector - Flow Rate Limit N/A - No Network Activity Posted Fri September 20, 2019 02:44 AM Hi Everyone,With tcpdump I can confirm that I'm getting traffic from the Span Port in my Flow Collector, then I go to the Console in the Network Activity tab and I dont see any traffic.I already created a flow source, I selected the right interface... Strange thing that I dont know if it's normal.In System and License Management on the Flow Rate Limit the Flow Collector has N/A... its a flow collecor it should has some limit and when I try to change it I can't... so strange.Does anybody knows why?QRadar Version 7.3.2Best regards,Rafael Rodrigues------------------------------Rafael Rodrigues------------------------------ 2. RE: Flow Collector - Flow Rate Limit N/A - No Network Activity Posted Mon September 23, 2019 05:01 AM Hi Rafael, Flow licenses are enforced on Flow Processors, Event/Flow Processors or on the Console. They are not enforced on the individual QNI or Flow Collector appliances. As a result, you will see N/A here. To do some basic debugging look at /var/log/qradar.log for messages from QFlow. Here you should see minute-by-minute statistics for the number of flows being received on the configured interface(s) as well as a number of sent flows. That will help identify where flows may not be being processed. I would probably encourage you to raise a support ticket to investigate this further.------------------------------Dale BowieQRadar Network Insights and Incident Forensics Product OwnerIBM------------------------------ 3. RE: Flow Collector - Flow Rate Limit N/A - No Network Activity Posted Tue September 24, 2019 10:37 AM Flow Licenses are enforced on an 31xx ALL IN ONE IBM QRadar deployment as well as a Distributed deployment which requires a 31xx Console and a Flow Processor17xx or a 18xx combination Event/Flow processor. If you only have a 16XX event Processor the only way to ingest flows is like other SIEMS that struggle with value from flows since they flatten Flows into Syslog.QFLOW and QNI require a Flow Processor as outlined above.If you did not purchase an All In One, or a Flow or Event/flow combination Flow Processor I don't see any value in purchasing QNI or QFlow as they are collectors NOT processors.------------------------------Richard GingrasQRadar SMEIBM SecurityCambridge MA------------------------------One-Hour Chill Yoga Music Flow

An accessible, cloud-based platform for building and managing cash flow projections. Its flexibility, ease of use, and real-time collaboration features make it ideal for tracking transactions and forecasting cash flow.Using formulas and templates, Google Sheets can automate cash flow forecast creation.The FORECAST function in Google Sheets can calculate expected cash inflows and outflows based on historical data.Automating cash flow forecast creation can save businesses time and reduce errors.How to choose the right cash flow templateVarious cash flow analysis and forecast templates are available for Google Sheets, each with different features and functionalities.Businesses should choose a template that meets their needs and is easy to use.A simple cash flow template or spreadsheet can be a good starting point for small businesses or startups.Free cash flow projection template for Google SheetsHere is an example of a free downloadable cash flow projection Google Sheet template:12-Month Cash Flow Template by Coefficient👉Download linkChart your business's financial future with this 12-month simple cash flow template. Enter your email, and you can download this free cash flow template.How can Shoeboxed help with cash flow management?By integrating Shoeboxed into your expense management, you can enhance the accuracy and efficiency of your cash flow projections.Here's how Shoeboxed can help:1. Streamlines expense trackingShoeboxed allows you to digitize all your receipts and expenses so they're all in one place and easily accessible.Use your smartphone to snap a picture of your receipt or document, and Shoeboxed's app will automatically upload a copy to your designated Shoeboxed account.This provides users with a comprehensive record of expenses all in one place.If you don't want to deal with the hassle of scanning, you can outsource your scanning by mailing your receipts or documents to Shoeboxed using their free pre-paid Magic Envelope. Their team will scan, human-verify, and upload them into your account for you.Shoeboxed is. Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct Flow Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct FlowSwiftKey Flow Review - One Click Root

Home Control valve Online calculator calculation of flow coefficient - Cv or Kv online since 2007 Description Control valve calculator is suitable for turbulent flow of liquids. The calculator is calculating flow coefficient Cv/Kv using the relationship between pressure drop and flow rate in the control valve which is for complete turbulent flow following power law where flow coefficient Cv/Kv is the proportional constant. save/open multiple resultsexport to Word and Excelprint resultscreate list of custom fluid propertiesresistance factor K for flow in valves and fittingspipe surface roughness selectionpipe material selectionselect between gauge and absolute pressurecompressible isothermal flowdry air isothermal flowgas offtake flownatural gas flowADMINISTRATOR ROLE NOT NEEDED Registration and subscription Select a subscription plan and enable the full service: Switch between metric and imperial units in one click Export calculation results in Word .docx or Excel .xlsx format Preview results on one place and copy/paste it in your favorite text editor Send results back to your email Support the future of this project And even more... Subscribed users have access to the full set of 19 calculators available as Java™ Web start application or download Windows™ 64bit application. Subscribe Full year service Monthly cost $250/month Full year service $29.95/year Flow rates and velocityvolume flow rate (q)mass flow rate (ṁ)velocity (V)internal diameter (D)Coefficients and pressure dropflow coefficient (Cv)flow coefficient (Kv)pressure drop (Δp) Exclusive calculator On exclusive calculator page you can use the online calculator without interference from advertisements, additional text, links and other content that is not required for the calculationsComments

Themselves. A pure experience of using a calculator as with a desktop application. An exclusive version of the calculator is available to registered users. Choose the right subscription duration and start using the exclusive service. Exclusive Description q - volumetric flow rateFluid flow rate in terms of units of volume per unit of time ṁ - mass flow rateFluid flow rate in terms of units of mass per unit of time V - velocityFlow velocity in terms of units of distance per unit of time D - internal diameterInternal circular pipe diameter Cv - flow coefficientIn imperial units - gpm Kv - flow coefficientIn metric units - m3/h p - pressureFluid pressure at the start of the pipe for gas density calculation based on the ideal gas state equation ρ - fluid densityMass per unit of volume Calculation setup Select value to calculate. You should enter not selected one. q/ṁ Calculate flow rate ΔpCalculate pressure drop Cv/KvCalculate flow coefficient Select value to input. You should enter selected one. The other one will be calculated q volumetric flow rate ṁ mass flow rate Select value to input. You should enter selected one. The other one will be calculated. Cv flow coefficient in imperial units - gpm Kv flow coefficient in metric units - m3/h Select value to input. You should enter selected one. The other one will be calculated. v flow velocity D internal pipe diameter When is this calculator suitable? To select a size of a control valve, you should

2025-04-01The protocol that permits this is called NetFlow. It was created by Cisco Systems several years ago but it is now commonly used in one form or another on networking equipment from most major manufacturers.What Is NetFlow?NetFlow was developed by Cisco Systems and was introduced on their routers to provide the ability to collect IP network traffic as it enters or exits an interface. The collected data is then analyzed by network administrators to help determine the source and destination of traffic, the class of service, and the causes of congestion.The flow exporter aggregates packets into flows and exports flow records towards one or more flow collectors. This is the component that is running on the monitored devices.The flow collector is responsible for reception, storage and pre-processing of flow data received from a flow exporter.Finally, the flow analyzer is an application that is used to analyze received flow data. Analysis can be used for traffic profiling, or for network troubleshooting.How NetFlow WorksRouters, switches and any other device that supports NetFlow can be configured to output flow data in the form of flow records and send them to a NetFlow collector. A flow is a complete conversation in the IP sense. The device preparing flow records normally sends them to the collector when it determines that the flow is finished either through aging–there has not been any traffic within a specific timeout–or when it sees a TCP session termination.The flow record contains a lot of information about the flow. It includes

2025-04-11Across a wide range of sizes and models. Copper has a melting point of 1,083°C and a normal maximum operating temperature of 225°C. Nickel, with a melting point of 1,453°C, can be used for specialist applications requiring higher temperatures and fluids aggressive to copper, with a maximum operating temperature of 350°C.Following brazing, the units are tested for leaks, using inert gas, ensuring that there is no external or internal leakage. They are pressure-tested typically at a pressure 50% higher than the normal maximum operating pressure.BPHE operationThe operating principle of a BPHE is based on the simple transfer of heat energy from the warmer media to the cooler one. The secondary side always has one more flow channel than the primary side – provided by the first and last channels – and contains the secondary fluid surrounding the primary channel. The secondary circuit also has a lower pressure drop because it contains one more (parallel) channel.The flow arrangement can be either counter flow or parallel flow (Figure 2).Figure 2: Temperature profiles for counter flow and parallel flow BPHECounter flow is preferred, since it enables a closer approach temperature (this is the temperature difference between the inlet of the primary and the outlet of the secondary flows), as well as a greater total heat exchange. As with any heat exchanger, the heat transfer from one flow to the other through a BPHE can be determined from U A ΔTLM, where U is the average thermal transmittance from one flow to the other (W·m-2·K-1); A is the overall heat transfer area (m2); and ΔTLM is the log mean temperature difference between the two flows.ΔTLM – often referred to as LMTD – is determined from the entering and leaving primary and secondary temperatures:So, for example, referring to the recommended system temperatures in Table 2

2025-04-10‘Yes’ side of the flow path to delete the records contained in the selectedRows collection of the data table. And that is it! The flow now looks like this: When we debug the flow with a Contact that is currently subscribed to one Email List, the first screen looks like this:On the next screen, we make some selections: When we push the “Update Selections” button, the flow makes the changes and ends. In cases when used on an actual record page or Salesforce Experience Site page, the flow would automatically start over and show us the first screen again with our changes made: ConclusionThis Flow was a lot of fun to build, and we hope you learned something! This is just one example of the great things that can be done with Salesforce Flows. Follow us on social or subscribe to our monthly newsletter to stay up-to-date on all things Salesforce and automation. Other blogs to explore:• Salesforce Flow Basics: Data, Elements, Decision and Assignment• Using Slack Workflows to Manage Customer Support Requests• Salesforce Flow Basics: Loop, Collection Sort, and Collection Filters• Salesforce Flow Basics: Screen, Pause, Action, and Subflow• Salesforce Flow Basics: Variables, Collections, and Formulas About the Author Jonathan Davis

2025-03-28