One flow

Author: t | 2025-04-25

Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct Flow

What is One Piece Flow? (Continuous Flow Single Piece Flow)

Themselves. A pure experience of using a calculator as with a desktop application. An exclusive version of the calculator is available to registered users. Choose the right subscription duration and start using the exclusive service. Exclusive Description q - volumetric flow rateFluid flow rate in terms of units of volume per unit of time ṁ - mass flow rateFluid flow rate in terms of units of mass per unit of time V - velocityFlow velocity in terms of units of distance per unit of time D - internal diameterInternal circular pipe diameter Cv - flow coefficientIn imperial units - gpm Kv - flow coefficientIn metric units - m3/h p - pressureFluid pressure at the start of the pipe for gas density calculation based on the ideal gas state equation ρ - fluid densityMass per unit of volume Calculation setup Select value to calculate. You should enter not selected one. q/ṁ Calculate flow rate ΔpCalculate pressure drop Cv/KvCalculate flow coefficient Select value to input. You should enter selected one. The other one will be calculated q volumetric flow rate ṁ mass flow rate Select value to input. You should enter selected one. The other one will be calculated. Cv flow coefficient in imperial units - gpm Kv flow coefficient in metric units - m3/h Select value to input. You should enter selected one. The other one will be calculated. v flow velocity D internal pipe diameter When is this calculator suitable? To select a size of a control valve, you should Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct Flow Putty Push/ Sandwich/ Invisalign (Two materials, one step) Monophase (One material, one step) Monophase (One material, one step) Heavy Tray Light Flow/Correct Flow Heavy Tray/Putty Light Flow/Medium Flow Putty Light Flow Fast Scan Putty, (Heavy Tray Light Flow/Medium Flow) Heavy Tray Medium Flow/Correct Flow The protocol that permits this is called NetFlow. It was created by Cisco Systems several years ago but it is now commonly used in one form or another on networking equipment from most major manufacturers.What Is NetFlow?NetFlow was developed by Cisco Systems and was introduced on their routers to provide the ability to collect IP network traffic as it enters or exits an interface. The collected data is then analyzed by network administrators to help determine the source and destination of traffic, the class of service, and the causes of congestion.The flow exporter aggregates packets into flows and exports flow records towards one or more flow collectors. This is the component that is running on the monitored devices.The flow collector is responsible for reception, storage and pre-processing of flow data received from a flow exporter.Finally, the flow analyzer is an application that is used to analyze received flow data. Analysis can be used for traffic profiling, or for network troubleshooting.How NetFlow WorksRouters, switches and any other device that supports NetFlow can be configured to output flow data in the form of flow records and send them to a NetFlow collector. A flow is a complete conversation in the IP sense. The device preparing flow records normally sends them to the collector when it determines that the flow is finished either through aging–there has not been any traffic within a specific timeout–or when it sees a TCP session termination.The flow record contains a lot of information about the flow. It includesComments

Themselves. A pure experience of using a calculator as with a desktop application. An exclusive version of the calculator is available to registered users. Choose the right subscription duration and start using the exclusive service. Exclusive Description q - volumetric flow rateFluid flow rate in terms of units of volume per unit of time ṁ - mass flow rateFluid flow rate in terms of units of mass per unit of time V - velocityFlow velocity in terms of units of distance per unit of time D - internal diameterInternal circular pipe diameter Cv - flow coefficientIn imperial units - gpm Kv - flow coefficientIn metric units - m3/h p - pressureFluid pressure at the start of the pipe for gas density calculation based on the ideal gas state equation ρ - fluid densityMass per unit of volume Calculation setup Select value to calculate. You should enter not selected one. q/ṁ Calculate flow rate ΔpCalculate pressure drop Cv/KvCalculate flow coefficient Select value to input. You should enter selected one. The other one will be calculated q volumetric flow rate ṁ mass flow rate Select value to input. You should enter selected one. The other one will be calculated. Cv flow coefficient in imperial units - gpm Kv flow coefficient in metric units - m3/h Select value to input. You should enter selected one. The other one will be calculated. v flow velocity D internal pipe diameter When is this calculator suitable? To select a size of a control valve, you should

2025-04-18The protocol that permits this is called NetFlow. It was created by Cisco Systems several years ago but it is now commonly used in one form or another on networking equipment from most major manufacturers.What Is NetFlow?NetFlow was developed by Cisco Systems and was introduced on their routers to provide the ability to collect IP network traffic as it enters or exits an interface. The collected data is then analyzed by network administrators to help determine the source and destination of traffic, the class of service, and the causes of congestion.The flow exporter aggregates packets into flows and exports flow records towards one or more flow collectors. This is the component that is running on the monitored devices.The flow collector is responsible for reception, storage and pre-processing of flow data received from a flow exporter.Finally, the flow analyzer is an application that is used to analyze received flow data. Analysis can be used for traffic profiling, or for network troubleshooting.How NetFlow WorksRouters, switches and any other device that supports NetFlow can be configured to output flow data in the form of flow records and send them to a NetFlow collector. A flow is a complete conversation in the IP sense. The device preparing flow records normally sends them to the collector when it determines that the flow is finished either through aging–there has not been any traffic within a specific timeout–or when it sees a TCP session termination.The flow record contains a lot of information about the flow. It includes

2025-04-08Across a wide range of sizes and models. Copper has a melting point of 1,083°C and a normal maximum operating temperature of 225°C. Nickel, with a melting point of 1,453°C, can be used for specialist applications requiring higher temperatures and fluids aggressive to copper, with a maximum operating temperature of 350°C.Following brazing, the units are tested for leaks, using inert gas, ensuring that there is no external or internal leakage. They are pressure-tested typically at a pressure 50% higher than the normal maximum operating pressure.BPHE operationThe operating principle of a BPHE is based on the simple transfer of heat energy from the warmer media to the cooler one. The secondary side always has one more flow channel than the primary side – provided by the first and last channels – and contains the secondary fluid surrounding the primary channel. The secondary circuit also has a lower pressure drop because it contains one more (parallel) channel.The flow arrangement can be either counter flow or parallel flow (Figure 2).Figure 2: Temperature profiles for counter flow and parallel flow BPHECounter flow is preferred, since it enables a closer approach temperature (this is the temperature difference between the inlet of the primary and the outlet of the secondary flows), as well as a greater total heat exchange. As with any heat exchanger, the heat transfer from one flow to the other through a BPHE can be determined from U A ΔTLM, where U is the average thermal transmittance from one flow to the other (W·m-2·K-1); A is the overall heat transfer area (m2); and ΔTLM is the log mean temperature difference between the two flows.ΔTLM – often referred to as LMTD – is determined from the entering and leaving primary and secondary temperatures:So, for example, referring to the recommended system temperatures in Table 2

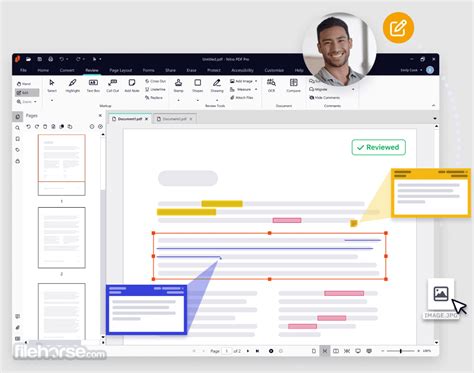

2025-04-24‘Yes’ side of the flow path to delete the records contained in the selectedRows collection of the data table. And that is it! The flow now looks like this: When we debug the flow with a Contact that is currently subscribed to one Email List, the first screen looks like this:On the next screen, we make some selections: When we push the “Update Selections” button, the flow makes the changes and ends. In cases when used on an actual record page or Salesforce Experience Site page, the flow would automatically start over and show us the first screen again with our changes made: ConclusionThis Flow was a lot of fun to build, and we hope you learned something! This is just one example of the great things that can be done with Salesforce Flows. Follow us on social or subscribe to our monthly newsletter to stay up-to-date on all things Salesforce and automation. Other blogs to explore:• Salesforce Flow Basics: Data, Elements, Decision and Assignment• Using Slack Workflows to Manage Customer Support Requests• Salesforce Flow Basics: Loop, Collection Sort, and Collection Filters• Salesforce Flow Basics: Screen, Pause, Action, and Subflow• Salesforce Flow Basics: Variables, Collections, and Formulas About the Author Jonathan Davis

2025-04-25